Top 10 Benefits of Using Injection Machine Robots in Manufacturing?

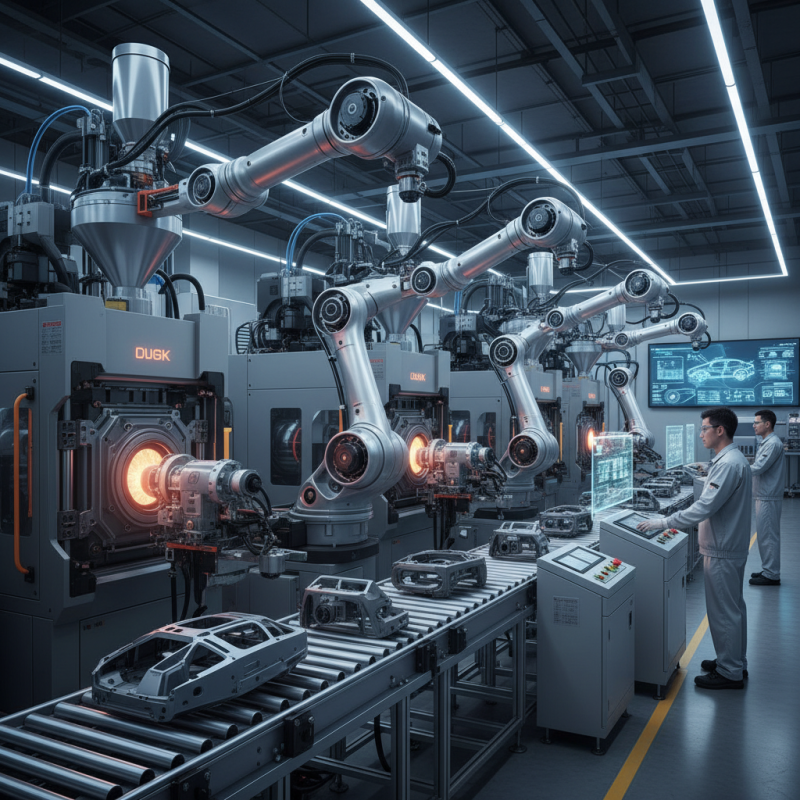

In today's competitive manufacturing landscape, the adoption of Injection Machine Robots has become essential. A report by MarketsandMarkets indicates that the global market for industrial automation is expected to reach $295 billion by 2025. This growth underscores the increasing reliance on advanced technologies in production processes.

John Adams, a leading expert in automation, emphasizes, "Injection Machine Robots offer unprecedented precision and efficiency in manufacturing." His insight reflects a broader industry trend towards automation, driven by the necessity for quality and cost-effectiveness. With Injection Machine Robots, manufacturers can enhance productivity while minimizing errors.

However, integrating these robots isn't without challenges. Many companies face issues related to training staff and initial costs. The potential for job displacement raises further concerns about the future workforce. Thus, while the benefits are substantial, manufacturers must think critically about the implications of this technology.

Advantages of Injection Machine Robots: A 2023 Manufacturing Perspective

The use of injection machine robots in manufacturing has gained momentum in 2023. Efficiency is one of the key advantages. Reports show that automated systems can improve production speed by up to 30%. This increase stemmed from reduced downtime and fewer errors. With robots handling repetitive tasks, human workers can focus on more complex activities.

Cost reduction is another benefit. Companies report savings of nearly 20% on labor costs when integrating robots. The upfront investment is significant, yet the long-term returns are compelling. However, the initial training for staff can be a stumbling block. Workers may resist adapting to new technology, impacting the overall transition process.

Quality control also improves. Data indicates that defects can be minimized by 50% with robotic precision. However, this does not eliminate all errors. Ongoing monitoring is crucial. While robots enhance productivity, they require human oversight. Balancing automation and human skill remains a challenge. The future of manufacturing will depend on how well these elements coexist.

Top 10 Benefits of Using Injection Machine Robots in Manufacturing

Cost Reduction: How Automation Lowers Production Costs by 30%

In recent years, automation has transformed manufacturing landscapes. Injection machine robots, in particular, excel in cost reduction. According to a report by the International Federation of Robotics, companies using automation can reduce production costs by up to 30%. This significant decrease allows businesses to reinvest in innovation and development rather than being bogged down by traditional processes.

Automating repetitive tasks increases efficiency as well. Robots can operate around the clock, minimizing downtime. A study published in the Journal of Manufacturing Science shows that labor costs can be cut by over 25% when robots are implemented. Yet, some companies struggle with the initial investment. The upfront costs of robotic systems can be daunting, and not every manufacturer sees immediate return on investment.

Additionally, while robots enhance precision, they are not free of challenges. Technical malfunctions can lead to costly delays. Regular maintenance is essential, which adds to overheads. Meanwhile, there is a continuous need for worker retraining to manage these machines effectively. Balancing automation with human expertise remains a complex but necessary endeavor for many manufacturers today.

Top 10 Benefits of Using Injection Machine Robots in Manufacturing

| Benefit | Description | Impact on Costs (%) |

|---|---|---|

| Cost Reduction | Automation reduces labor costs and operational inefficiencies. | 30% |

| Increased Production Speed | Robots work faster than humans, increasing output. | 25% |

| Higher Precision | Robots provide consistent and precise manufacturing processes. | 20% |

| Reduced Waste | Automation optimizes material usage, decreasing scrap rates. | 15% |

| Improved Safety | Robots take over dangerous tasks, reducing workplace injuries. | 10% |

| Enhanced Flexibility | Robots can be reprogrammed for different tasks quickly. | 5% |

| Improved Quality Control | Sensors enhance quality checks and minimize defects. | 18% |

| Scalability | Facilitates easier scaling of production depending on demand. | 12% |

| Consistency | Robots deliver consistent results without fatigue. | 10% |

| Data Collection & Analysis | Robots can collect data for analytics and improvements. | 8% |

Increased Efficiency: The Role of Robots in Doubling Production Rates

The manufacturing industry is witnessing a revolution. Robots are now integral to injection molding processes. They significantly enhance efficiency by doubling production rates. This shift has transformed many factories into hubs of output and precision. The speed at which these robots operate minimizes downtime and maximizes throughput.

Implementing robots can seem daunting. The initial investment might raise concerns. However, the long-term benefits outweigh these challenges. For a smooth transition, companies should start small. Integrate one robot at a time. Evaluate its performance and adjust as needed. This incremental approach builds confidence in automation.

Regular training for workers is crucial. Proper training enhances the interaction between human operators and robotic systems. It can lead to unexpected efficiency gains. Remember, a well-trained workforce is adaptable. They can troubleshoot problems that arise during production. Mistakes may happen, but they are valuable lessons. Embracing them fosters improvement.

Precision and Quality Control: Achieving Tighter Tolerances with Robotics

In modern manufacturing, precision is paramount. Injection machine robots play a critical role in achieving this. They produce components with tighter tolerances. This reduces the likelihood of defects. By automating the injection process, manufacturers can maintain consistent quality across large batches.

One tip for maximizing precision is regular maintenance of the robotic systems. Ensure that all mechanical parts are well-lubricated. This helps maintain accuracy during operations. Additionally, using advanced sensors can enhance feedback loops, improving the overall production process. Be mindful; even the most advanced robots can encounter issues like alignment errors.

Quality control is not just about automation. It involves human oversight, too. Regularly check robot outputs to catch any anomalies. This is crucial because robots can miss minor flaws that might become significant later. Balancing technology and human judgment ensures optimal results.

Safety Enhancements: Reducing Workplace Injuries by 50% in Manufacturing

Injection machine robots are transforming the manufacturing industry, especially regarding workplace safety. Companies are reporting a significant reduction in injuries—often by as much as 50%. This figure is compelling and highlights the importance of automation in modern factories. Robots handle hazardous tasks, minimizing the risk to human workers.

The integration of these robots creates a safer environment. With precision and speed, they perform repetitive tasks that were once dangerous. However, the transition isn't without challenges. Workers may feel apprehensive about job security. Training programs are essential to help employees adapt to this new technology. It's crucial for management to recognize these concerns and address them effectively.

While the benefits are clear, there are still gaps. Not all manufacturers are ready to implement such advanced technology. Smaller companies might struggle with costs and resources. Moreover, the effectiveness of safety improvements depends on continuous monitoring and updates to safety protocols. Improvements in technology bring new challenges, urging companies to reflect and adapt continuously.